USING WSEC SERIES MOTORS WITH AUTOMATION SYSTEMS

Important Information

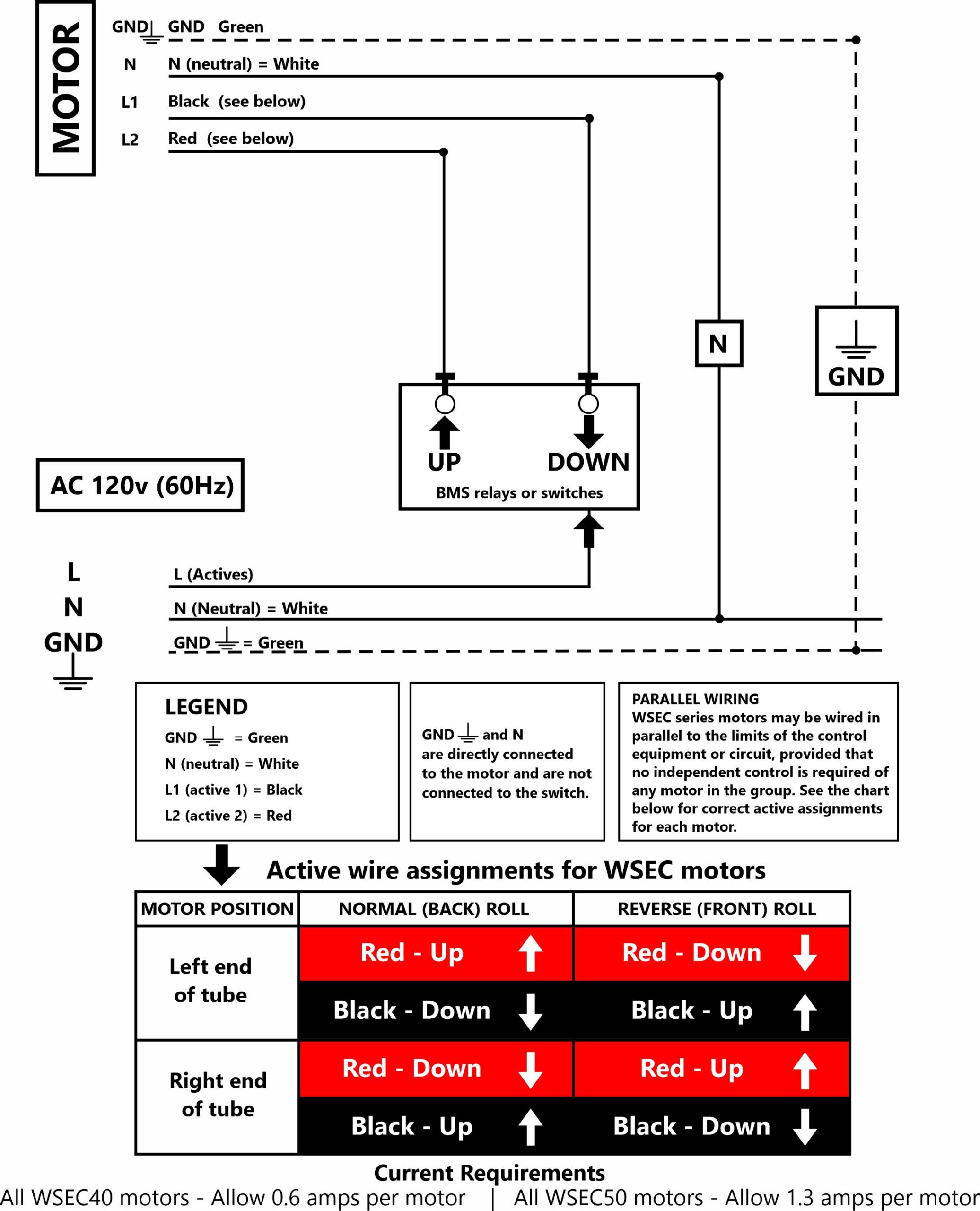

Like most other brands of blind, awning and shutter motors, Alpha produces motors designed to work with automation systems. These motors have a ground and neutral connection and use 2 separate active wires (black and brown) to control both the operation and direction of the motor. Simply put, if you apply power to the brown wire the motor will turn in one direction until either the power is cut or the motor reaches its internally set limit. The same is true of the black wire except that the motor turns in the opposite direction.

Never apply power to both active wires at the same time.

WSEC series motors are the most popular for use with automation systems due to the ability to parallel wire them and the use of electronic limits.

Setting and deleting limits is done by applying power to both actives at the same time for different periods. This is done by the blind installer using an Alpha limit setting tool. Once the limits are set they are rock solid except for the reasons specified below.

If at any time the automation system allows power to both actives at the same time, it can cause the motor to alter or delete its internal limits. Power to one direction MUST be cut before power is applied to the other direction. Failure to do this will likely cause the blind to be damaged due to the motor continuing to run for as long as it has power.

Please pay particular attention to the following points:

1. Do not connect the motors to the automation system until the programming is completed. These motors require much more care than items that are simply turned on or off in this respect. The programming must contain the points below before testing begins.

2. Programming must contain situational instructions that ensure power is cut to one direction before being connected to the other. One example of this might be what happens if someone issues an up command while power is being supplied for the down direction. Allow one second of delay between the motor running in one direction before switching power to the other direction.

3. Do not allow power to be supplied indefinitely to one direction. Use timers to cut power a few seconds after the motor reaches its limit. 5 seconds longer than the measured travel time would be plenty.

4. If the automation system has a test mode that it enters in certain situations, like after a power failure or after a program upload for example, this must be disabled if the test mode includes triggering the relays that control power to the blinds. In situations where there is more than one control system in play, check both control systems for this. For example, if C-Bus is controlling the motors but a Crestron or AMX system is issuing commands to C-Bus, make sure that both systems are checked.

5. If you have blinds operating in a group, make sure all blinds in that group start travelling at the same time. Blinds that start at different times cannot be stopped evenly between their set limits.

Connecting WSEC Motors to an Automation System